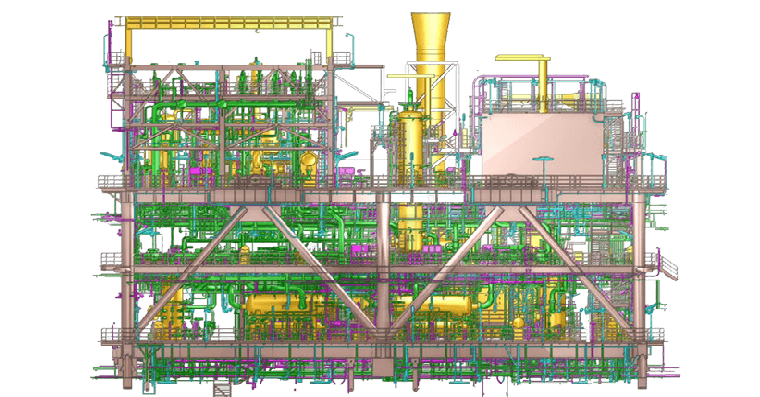

Engineering

empty

Read More >

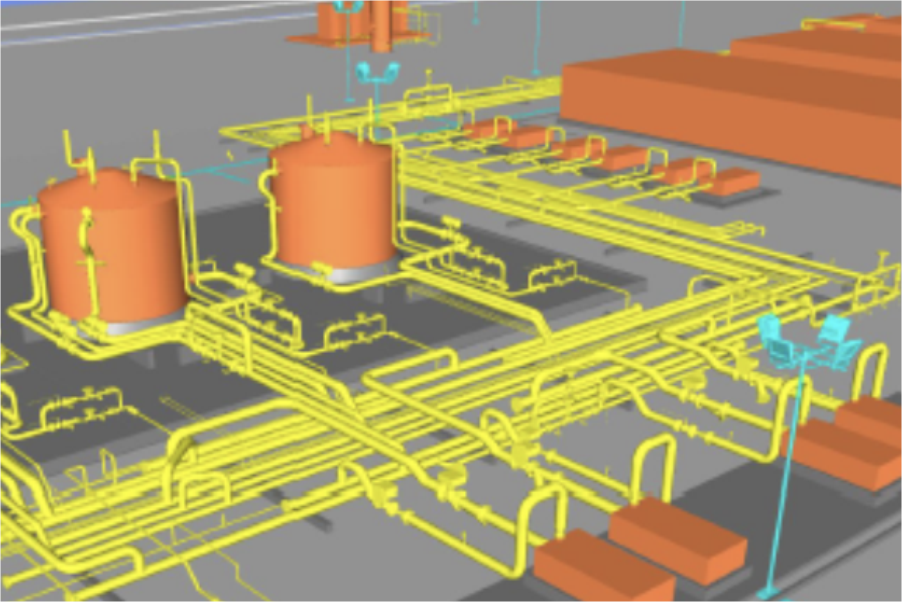

Chevron Agbami Gas Project

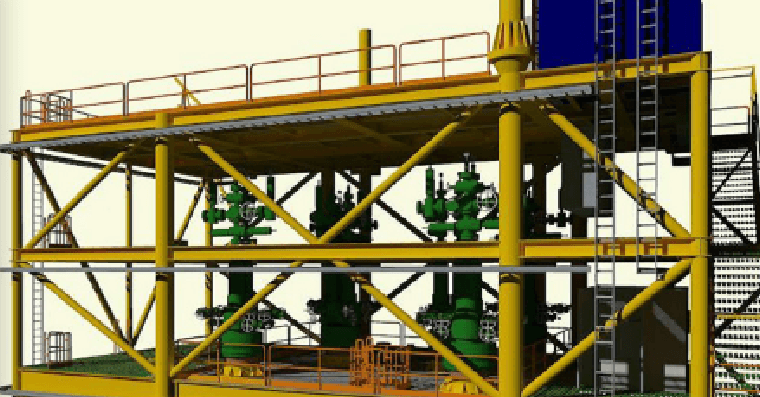

SNEPCO Bonga Smart Choke Installation Project

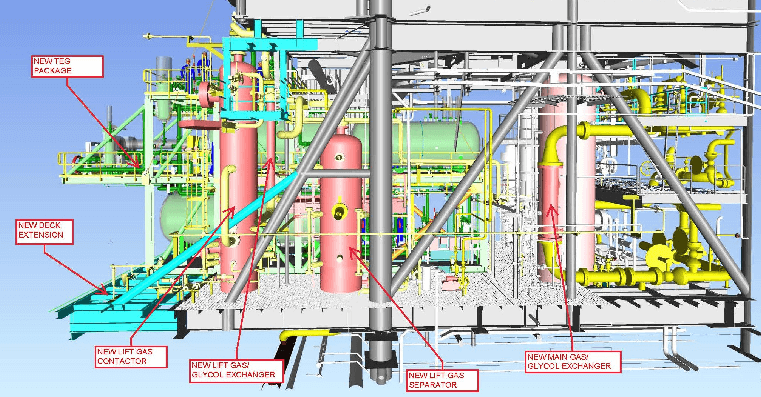

Chevron Makaraba Gas Development

Heritage Produced Water Treatment Design

First E&P OML 83 & 85 Development Project

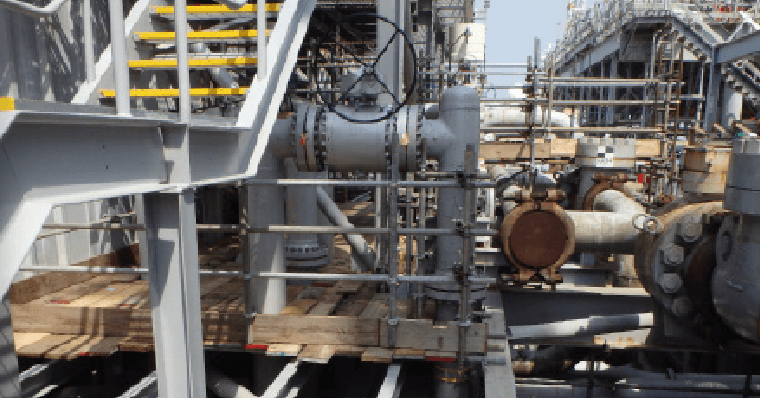

Construction

empty

Read More >

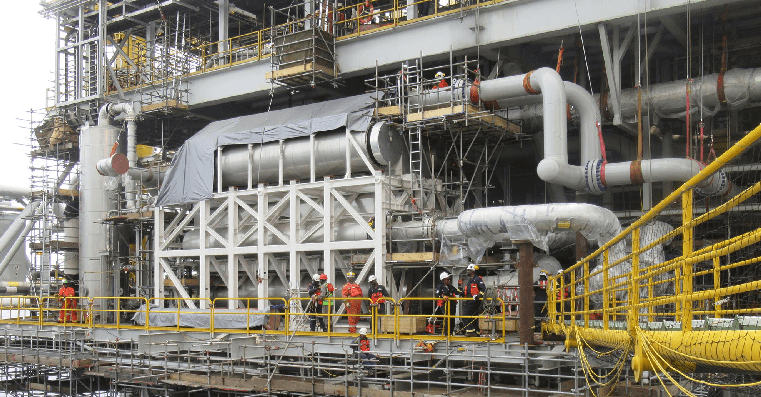

ExxonMobil Inlet Gas Exchanger (IGE) Replacement

Okan GGCP Debottlenecking

ExxonMobil Iyak B Platform Structural Revamp

ExxonMobil Utue KB Platform Structural Revamp

ExxonMobil Usari FA Platform Structural Revamp

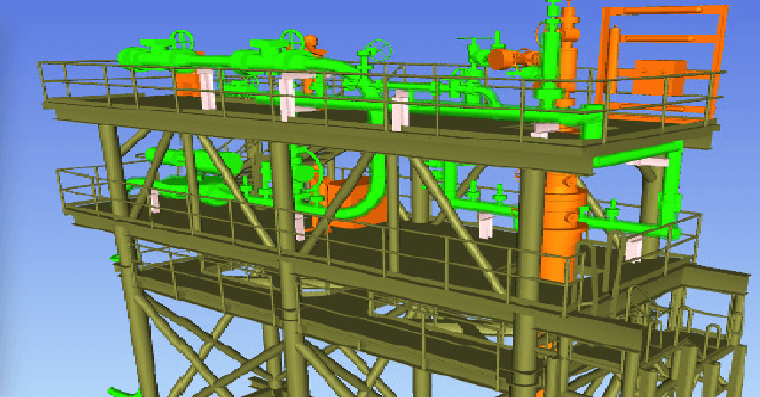

Installation

empty

Read More >

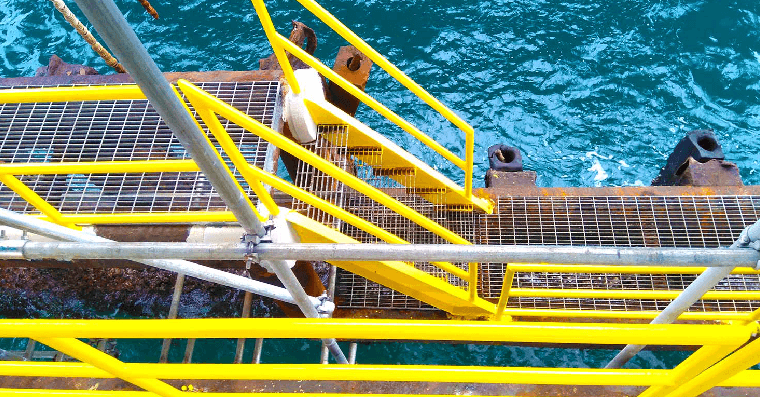

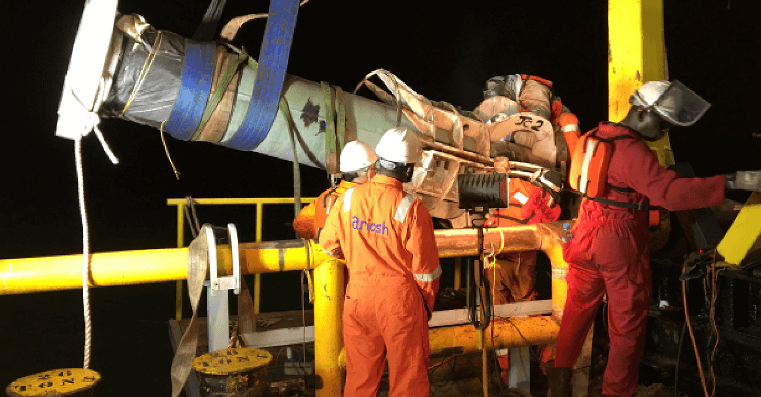

Chevron 24” Subsea Pipeline Repair Project

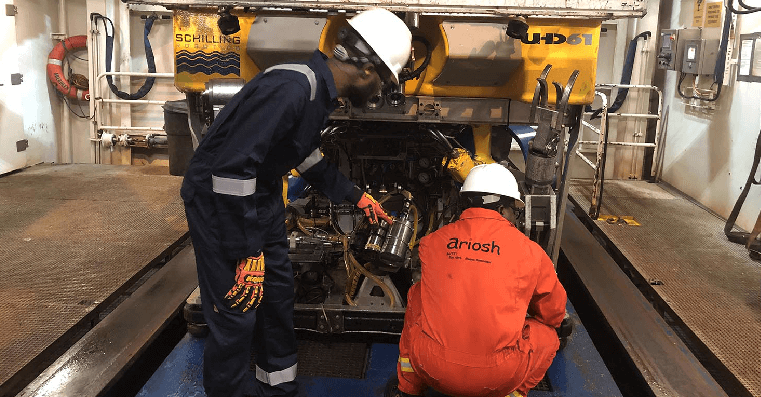

BW Offshore Sendje Berge Mooring Inspection