Ariosh is a leading provider

of 3D Laser Scanning

Services

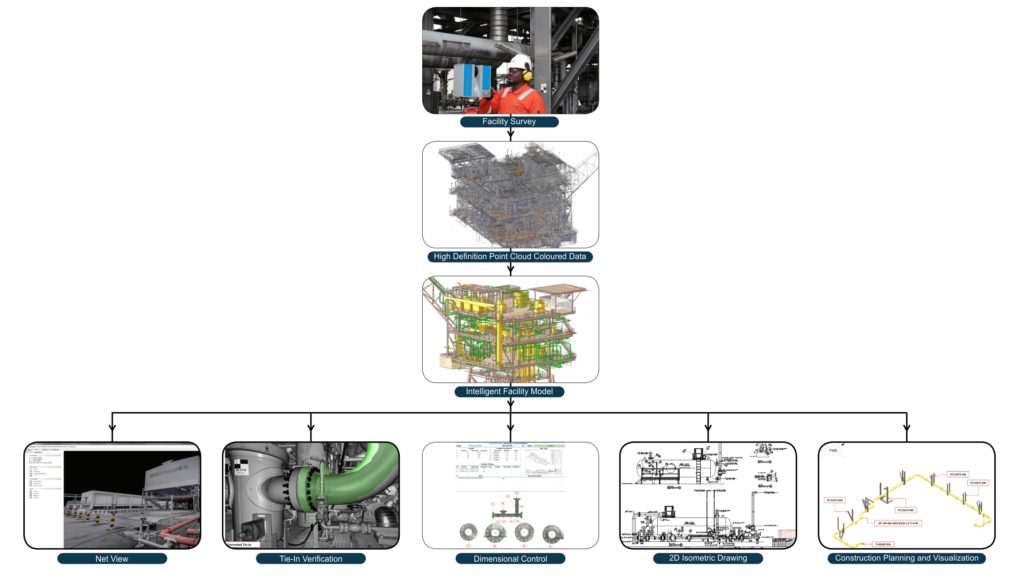

We deployed this innovative technology over a decade ago to support brownfield developments and successfully set a new paradigm for reverse engineering, seamless construction and first fit installation.

We utilize the latest high definition 3D scanning technology and our unique workflow to assist our clients in planning and executing projects more efficiently, helping them to minimize operational shutdowns and mitigate project risks. With a large fleet of laser scanners and highly trained team, our 3D laser scanning services have significantly faster turnaround time compared to other services providers.

We utilize the latest high definition 3D scanning technology and our unique workflow to assist our clients in planning and executing projects more efficiently, helping them to minimize operational shutdowns and mitigate project risks. With a large fleet of laser scanners and highly trained team, our 3D laser scanning services have significantly faster turnaround time compared to other services providers.

Digitize

Collaborate

Enhance

Digitize

3D As-built Laser Documentation.

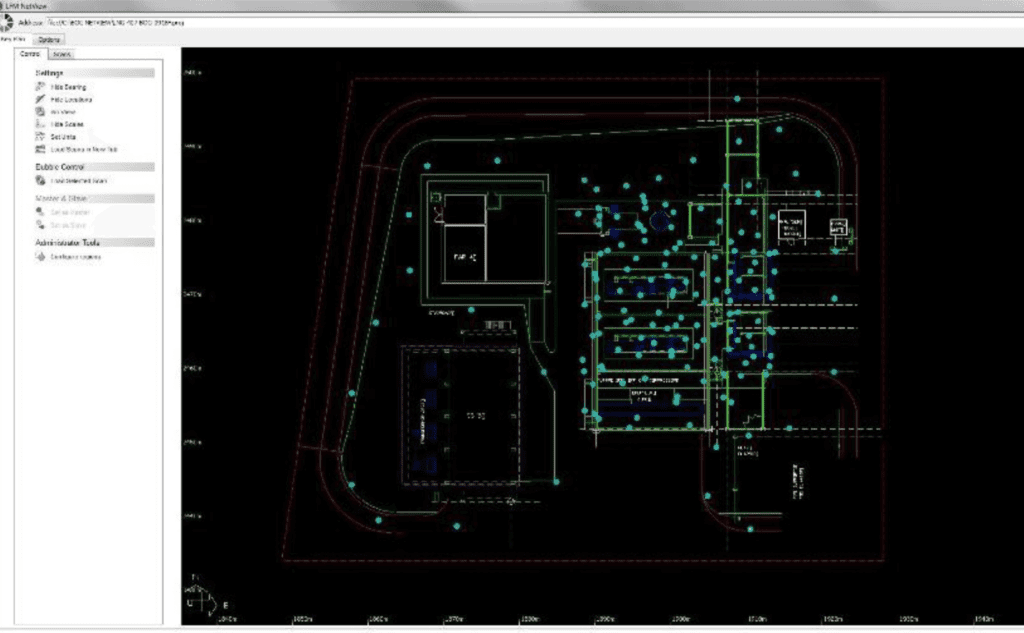

Ariosh laser scanning hub provides an accurate 3D facility database that can be viewed over the web or on local PCs. Facility owner/operators with limited or no experience in laser scanning, point cloud data, CAD, or 3D CAD can easily view, annotate, and take measurements of the digitized facility.

3D Point Cloud.

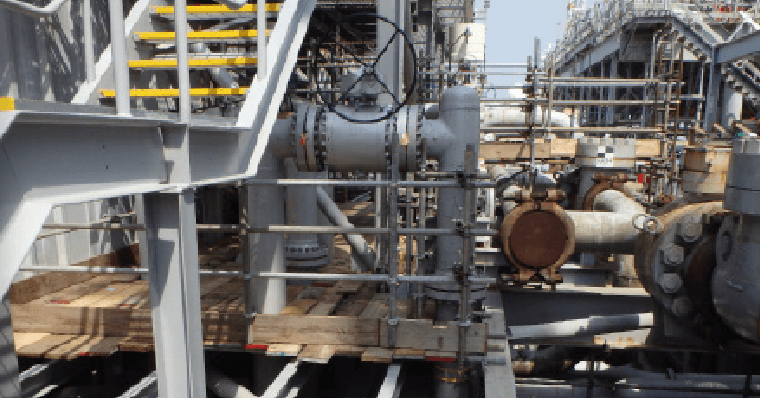

Laser Data acquired from existing facilities using high definition scanners are registered into a common set of cartesian coordinates. Subsequently, the acquired data is aligned orthogonally and position with respect to the facility coordinate system using Total Station.

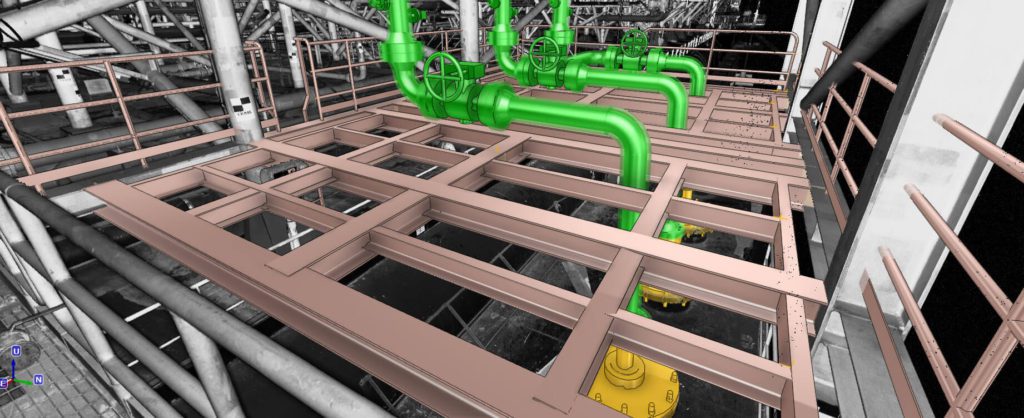

Superimposition.

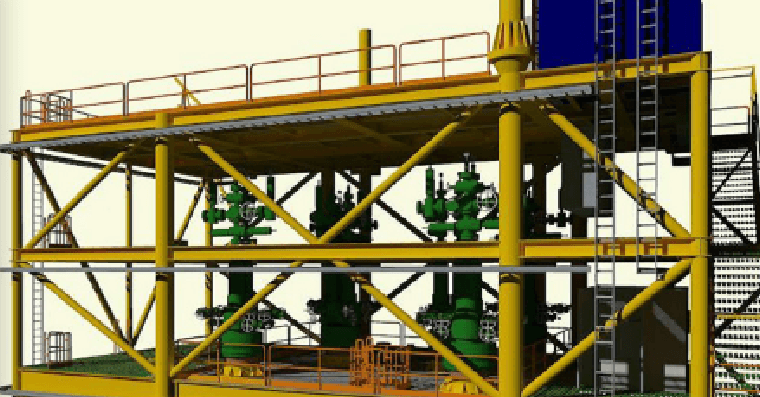

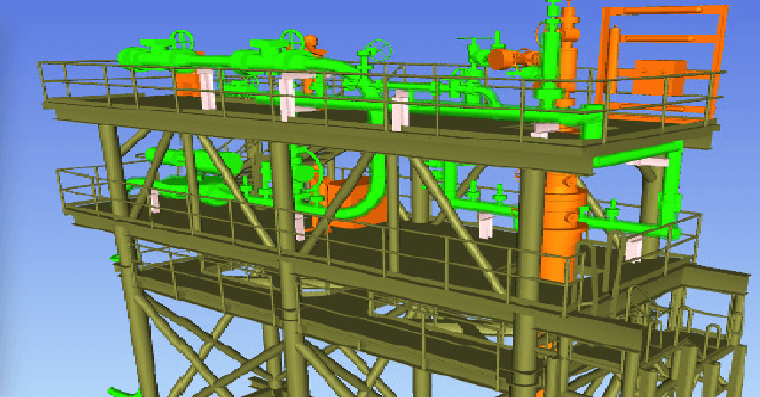

The PCD is imported into CAD software where it is systematically superimposed with intelligent 3D models. PDMS and other CAD software are employed by a modeller to trace and fit piping, equipment or structural members to the PCD.

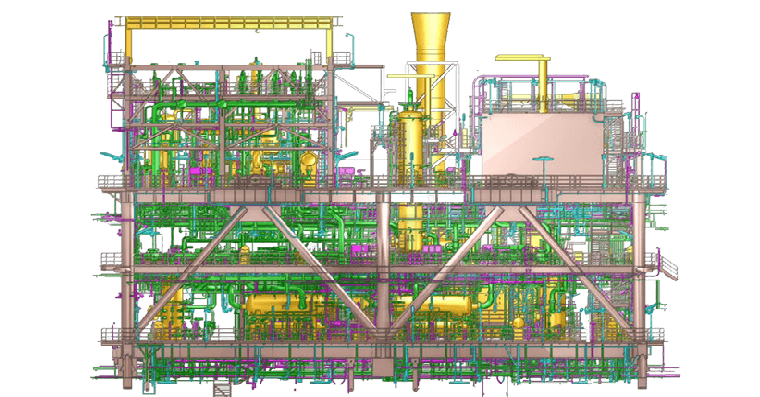

3D Plant CAD Models.

As-built information of a working facility is often inaccurate and incomplete, and becomes even more obsolete as time passes. Ariosh laser scanning hub mitigates these issues by using laser scan data to create validated, as-is 3D plant models for reverse engineering.

As Built Laser Data- NetView.

Laser Scan Data in a format that provides access to complete high-definition, photo-realistic as-built information of Digitized Facility Access, viewing, measurement and mark-up of Panoramic images of High – Definition PCD.

Remotely located team members can access real time as – is platform data with full mark-up capabilities locally or via the web and can also incorporate hyperlinks to asset information within views.

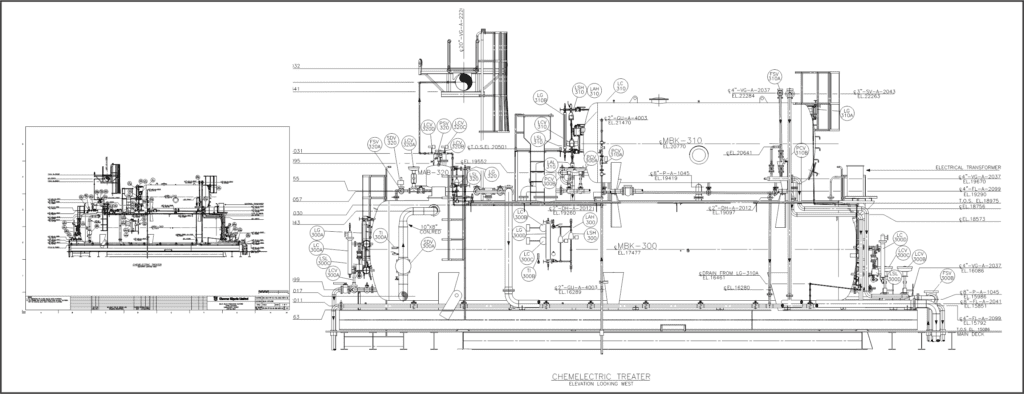

2D As-Built Drawings.

In addition to asset information management, accurate as-is drawings are essential for the FEED and Detailed Engineering Design (DED) activities. Ariosh expertly processes the digitized facility into standard 2D drawings, detailing complete and accurate existing conditions of the facility. One of our most established service offerings, we have produced over 300,000 as-built drawings in the past 5 years.

Collaborate

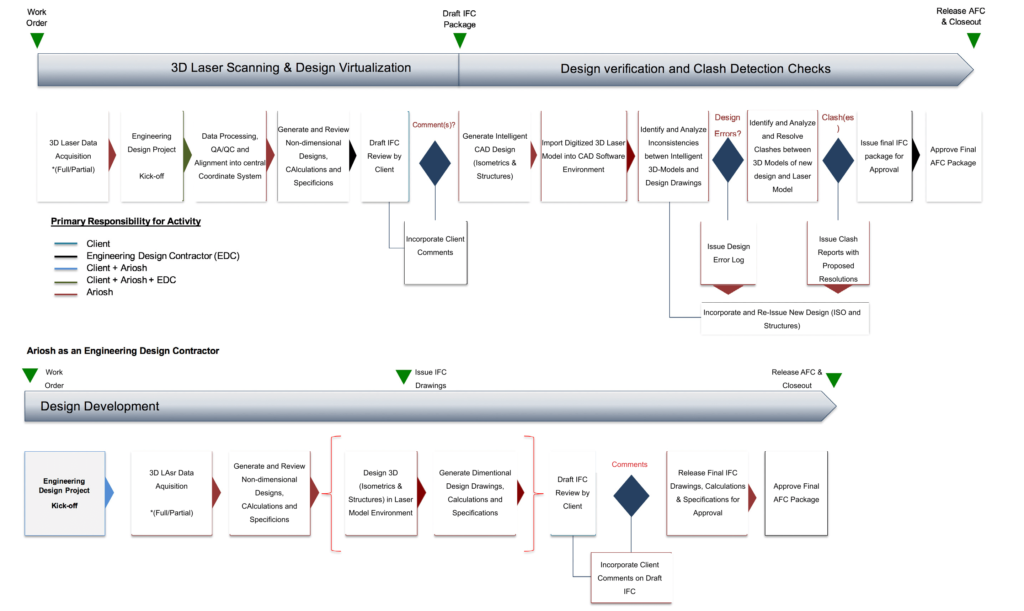

Ariosh as a QA/QC Contractor.

Ariosh Advantage.

Enhance

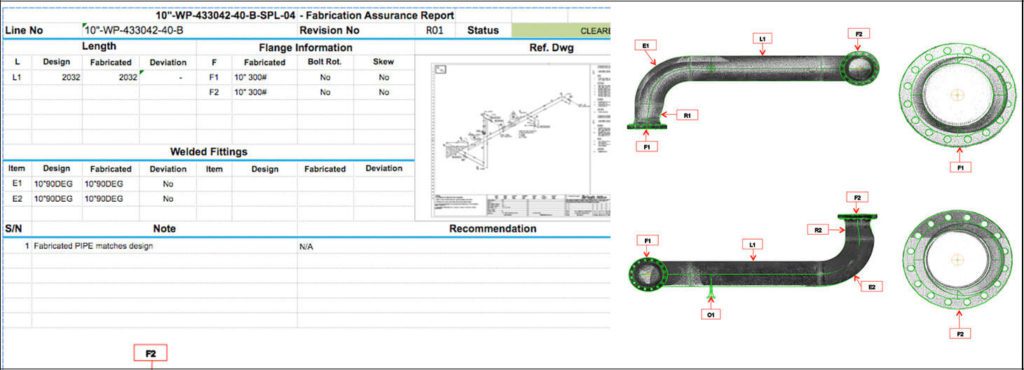

Design Verification (PipeFit Assurance).

The digital facility model, with its accuracy and comprehensive detail, can be used in the elimination of design errors.

Ariosh executes the following activities on final IFC packages to ensure spool piece and structural members bolt up at first install.

- Clash Check & Resolution

- Tie Point Extraction

- Design Validation, Modification & QA/QC

- Isometrics and Shop Drawing Generation

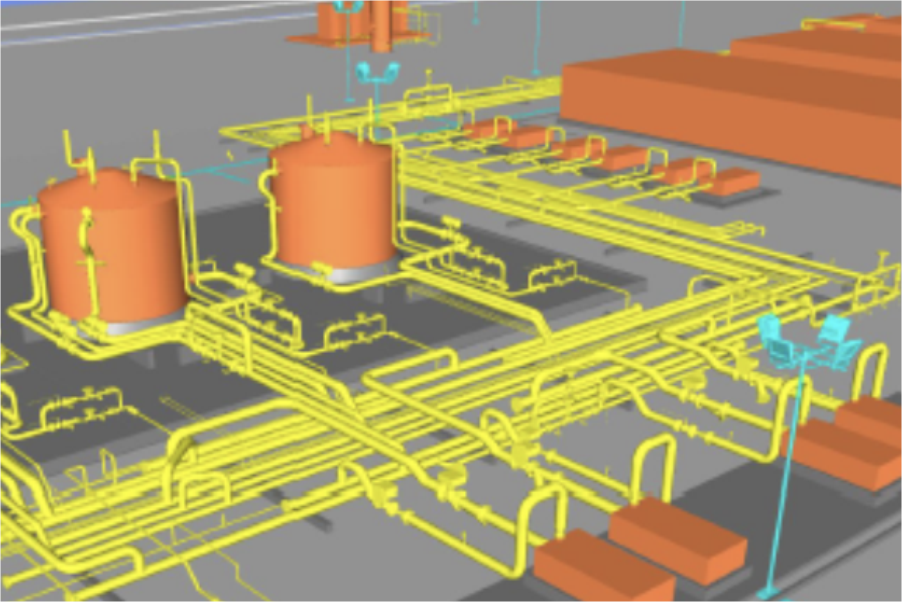

Construction Planning and Visualization.

Construction planning benefits the production team by facilitating the precise location of cut lines, and enabling the visualization of spool sequencing and lift planning, scaffold planning, and assembly simulations. The digitized facility model also enables the graphic visualization of new designs inside the existing facility so that all stakeholders can clearly understand how the pending additions will interact with the existing plant configuration.

Construction Work Packages (Job Cards).

Ariosh installation work package deliverables are stand-alone job cards, delineated by discipline. Every drawing referenced in relation to an installation activity is appended to each job card, along with time estimates and required resource indexes, and a complete list of materials and equipment critical to executing each task.

The installation job cards usually have TrueView and/or Navisworks snapshot pictures for better clarity of the installation.

Dimension Control (Fabrication Assurance).

Quality engineering design ensures that new designs do not clash with existing facilities. As part of our dimension control service, our laser scanning hub is used to verify the consistency of fabricated items by carrying out spool, lines and structural checks.

Recent Projects

empty

Read More >

Chevron Agbami Gas Project

SNEPCO Bonga Smart Choke Installation Project

Chevron Makaraba Gas Development

Heritage Produced Water Treatment Design